Cov khoom

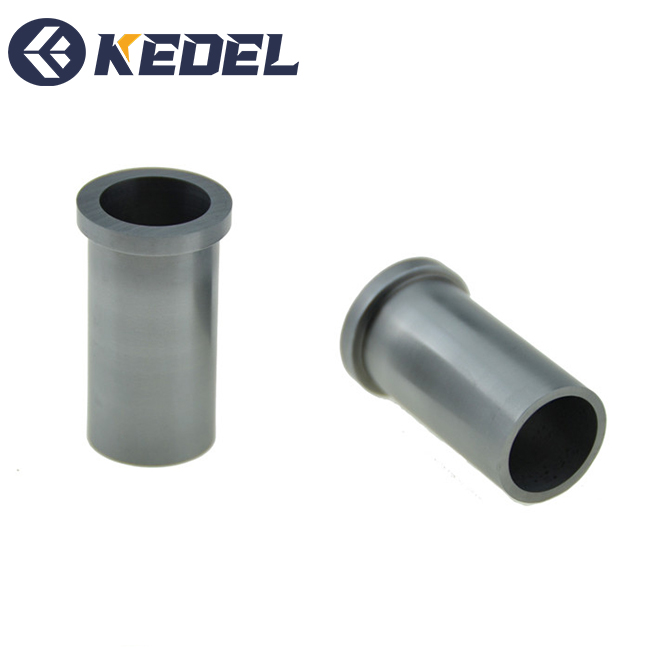

Anti Corrosion Tungsten Carbide Khoom YG1C Threaded Laum Bushings

Khoom Taw Qhia

Tungsten carbide bushing teeb tsa los ntawm cov khoom siv nkauj xwb tungsten carbide. Nws qhia tau hais tias siab hardness thiab dabtsi yog khoov zog. Qhov ntawd muaj kev ua tau zoo tshaj plaws ntawm kev tiv thaiv kev puas tsuaj thiab corrosion, uas yog siv dav hauv ntau lub lag luam

Rau nws siv dav. Tungsten carbide bushing feem ntau yog ua nrog cov neeg siab, thiab vim yog lawv cov tiav tiav, meej qhov ntev, durability thiab corrosion kuj. Cov no tau txais txiaj ntsig zoo los ntawm cov neeg siv khoom ntawm kev lag luam domistic thiab aboard.

Tsis tas li ntawd, sib txawv ntawm ntau yam ntawm daim ntawv thov ib puag ncig. Muaj ntau ntau hom tungsten carbide bushing. Feem ntau ntawm cov specifications yog tag nrho customized. Kedel Tool tau txhawb nqa los ntawm kev paub txog kev lag luam nplua nuj thiab kev tsim khoom ntawm ntau yam Tungsten carbide bushing. Qhov no tuaj yeem tsim ntau yam ntawm Tungsten carbide bushing raws li kev tsim tshwj xeeb.

Khoom nta

1. Siv 100% tungsten carbide raw khoom

2. Cov khoom siv tshuaj ruaj khov

3. Kev ua tau zoo heev thiab hnav zoo / corrosion kuj

4. HIP sintering, zoo compactness

5. Qhov khoob, siab machining raug / precision

6. OEM customized ntau thiab tsawg muaj

7. Lub Hoobkas muaj

8. Kev soj ntsuam xyuas cov khoom zoo

Daim duab nthuav dav

Cov ntaub ntawv

| Qib | ISO | Specification | Kev siv tungsten carbide | ||

| Qhov ntom | TRS | Hardness | |||

| G/Cm3 | N / hli 2 | HRA | |||

| yog 06x | K10 | 14.8-15.1 Nws | ≥1560 | ≥91.0 | Tsim nyog rau machining ntawm chilled cam khwb cia hlau, alloy cam khwb cia hlau, refractory steel thiab alloy hlau. Kuj Tsim nyog rau machining ntawm cov cam khwb cia hlau. |

| YG06 | K20 | 14.7-15.14 Nws. 1 | ≥1670 | ≥89.5 | Tsim nyog rau kev ua tiav machining thiab semi-finish machining rau cov cam khwb cia hlau, cov hlau tsis-ferrous, alloy thiab cov ntaub ntawv tsis siv. Kuj tseem tsim nyog rau kev kos duab hlau rau cov hlau thiab cov hlau tsis muaj hlau, hluav taws xob laum rau kev siv geology thiab steel laum thiab lwm yam. |

| YG08 | K20-K30 | 14.6-14.9 Nws | ≥1840 | ≥89 | Tsim nyog rau kev ua haujlwm ntxhib ntawm cov hlau cam khwb cia hlau, cov hlau tsis muaj hlau, cov ntaub ntawv tsis yog hlau, kos duab hlau, cov hlau tsis muaj hlau thiab cov kav dej, ntau yam kev xyaum siv geology, cov cuab yeej siv tshuab thiab hnav cov khoom. |

| YOG 09 | K30-M30 | 14.5-14.8 Nws | ≥2300 | ≥91.5 | Tsim nyog rau kev ua haujlwm qis qis, milling titanium alloy thiab refractory alloy, tshwj xeeb tshaj yog rau cov cuab yeej txiav tawm thiab cov kab lo lo ntxhuav. |

| YG11C | K40 | 14.3-14.6 Nws | ≥2100 | ≥86.5 | Tsim nyog rau molding cov xyaum rau hnyav-duty pob zeb xyaum: detachable khoom siv rau sib sib zog nqus qhov drilling, pob zeb laum trolley thiab lwm yam. |

| YG 15 | K40 | 13.9-14.1 Nws | ≥ 2020 | ≥86.5 | Tsim nyog rau cov pob zeb nyuaj drilling, steel tuav nrog siab compression ratios, yeeb nkab kos duab, xuas nrig ntaus cov cuab yeej, tub ntxhais txee ntawm hmoov metallurgy tsis siv neeg molders thiab lwm yam. |

| YG 20 | 13.4-14.8 Nws | ≥2480 | ≥83.5 | Tsim nyog rau kev ua tuag nrog kev cuam tshuam tsawg xws li xuas nrig ntaus qhov chaw, roj teeb plhaub, lub hau me me thiab lwm yam. | |

| YG 25 | 13.4-14.8 Nws | ≥2480 | ≥82.5 | Tsim nyog rau kev ua pwm ntawm lub taub hau txias, txias stamping thiab txias nias siv rau kev tsim khoom txheem, bearings thiab lwm yam. | |