Cov khoom

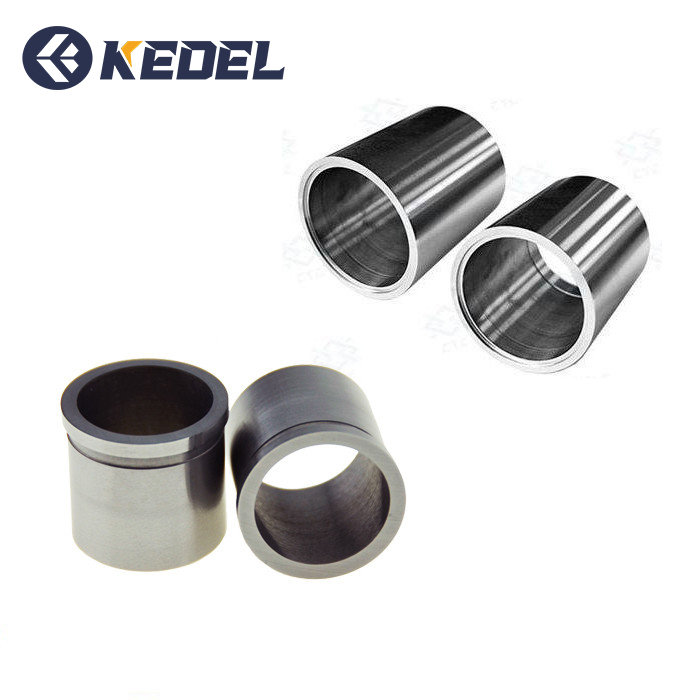

Cemented Tungsten Carbide Tes Tsho Bushings Rau Submersibe Roj Teb

Khoom Taw Qhia

Daim ntawv thov tungsten carbide lub tes tsho yog dav, uas yog ib qho khoom siv los tiv thaiv cov chav kawm ntawm cov khoom.Nws yog nyob rau hauv qhov tseeb ua hauj lwm thiab lub luag hauj lwm thiab lub hom phiaj ntawm nws daim ntawv thov ib puag ncig muaj kev sib raug zoo.

Daim ntawv thov valve, bushings yuav tsum tau ntsia rau hauv lub valve qia cap ntxiab, thiaj li yuav txo tau lub valve to, kaw;bearing daim ntaub ntawv, kev siv cov hav txwv yeem los txo qhov hnav ntawm cov kabmob thiab lub rooj zaum ntawm lub rooj zaum, zam qhov sib txawv ntawm cov ncej thiab lub qhov nce thiab lwm yam.

Tungsten carbide lub tes tsho ntau lawm thiab kev ua haujlwm ntawm lub zog siab, tuaj yeem tiv taus lub sijhawm ntev, nrog cov tshuaj lom neeg ruaj khov, alkali, cawv, ether, hydrocarbons, acid, roj, tshuaj ntxuav tes, dej ( dej hiav txwv), thiab tsis muaj ntxhiab tsw, tsis muaj tshuaj lom, tasteless, tsis-xeb yam ntxwv, nws lug siv nyob rau hauv petrochemical kev lag luam rau Submerged Roj twj tso kua mis, slurry twj tso kua mis, dej twj tso kua mis, Centrifugal Twj, thiab lwm yam.

qhov zoo

1, 100% Raw khoom:

Bushings yog tsim los ntawm cov ntaub ntawv ntshiab, uas muaj cov yam ntxwv ntawm kev ua haujlwm ntev thiab kev ua haujlwm ruaj khov.

2, Kev tsim kho:

Bushings yog ua tiav los ntawm cov khoom siv high-precision: CNC machining chaw, sib tsoo tshuab, milling tshuab, drilling tshuab, kab rov tav milling tshuab, chamfering tshuab, Hlau Stamping, CNC txiav tshuab thiab lwm yam.

3, Ntau qhov ntau thiab tsawg muaj:

Peb tuaj yeem muab cov kabmob bushings ntau qhov sib txawv, ua tiav pwm thiab lub sijhawm xa khoom luv.7-10 hnub rau cov qauv .20-25 hnub ua haujlwm rau cov khoom loj

4, Kev ruaj ntseg zoo:

Unsurpassed Quality Standards.Our bushings sleeves bearings yog tsim thiab tsim raws li cov qauv nruj nruj uas tswj cov khoom xaiv, machining, nto tiav, tshuaj xyuas thiab ntim.

Tsom iav

Daim duab nthuav dav

Cov ntaub ntawv

| Qib | ISO | Specification | Kev siv tungsten carbide | ||

| Qhov ntom | TRS | Hardness | |||

| G/Cm3 | N / hli 2 | HRA | |||

| yog 06x | K10 | 14.8-15.1 Nws | ≥1560 | ≥91.0 | Tsim nyog rau machining ntawm chilled cam khwb cia hlau, alloy cam khwb cia hlau, refractory steel thiab alloy hlau.Kuj Tsim nyog rau machining ntawm cov cam khwb cia hlau. |

| YG06 | K20 | 14.7-15.14 Nws.1 | ≥1670 | ≥89.5 | Tsim nyog rau kev ua tiav machining thiab semi-finish machining rau cov cam khwb cia hlau, cov hlau tsis-ferrous, alloy thiab cov ntaub ntawv tsis siv.Kuj tseem tsim nyog rau kev kos duab hlau rau cov hlau thiab cov hlau tsis muaj hlau, hluav taws xob laum rau kev siv geology thiab steel laum thiab lwm yam. |

| YG08 | K20-K30 | 14.6-14.9 Nws | ≥1840 | ≥89 | Tsim nyog rau kev ua haujlwm ntxhib ntawm cov hlau cam khwb cia hlau, cov hlau tsis muaj hlau, cov ntaub ntawv tsis yog hlau, kos duab hlau, cov hlau tsis muaj hlau thiab cov kav dej, ntau yam kev xyaum siv geology, cov cuab yeej siv tshuab thiab hnav cov khoom. |

| YOG 09 | K30-M30 | 14.5-14.8 Nws | ≥2300 | ≥91.5 | Tsim nyog rau kev ua haujlwm qis qis, milling titanium alloy thiab refractory alloy, tshwj xeeb tshaj yog rau cov cuab yeej txiav tawm thiab cov kab lo lo ntxhuav. |

| YG11C | K40 | 14.3-14.6 Nws | ≥2100 | ≥86.5 | Tsim nyog rau molding cov xyaum rau hnyav-duty pob zeb xyaum: detachable khoom siv rau sib sib zog nqus qhov drilling, pob zeb laum trolley thiab lwm yam. |

| YG 15 | K40 | 13.9-14.1 Nws | ≥ 2020 | ≥86.5 | Tsim nyog rau cov pob zeb nyuaj drilling, steel tuav nrog siab compression ratios, yeeb nkab kos duab, xuas nrig ntaus cov cuab yeej, tub ntxhais txee ntawm hmoov metallurgy tsis siv neeg molders thiab lwm yam. |

| YG 20 | 13.4-14.8 Nws | ≥2480 | ≥83.5 | Tsim nyog rau kev ua tuag nrog kev cuam tshuam tsawg xws li xuas nrig ntaus qhov chaw, roj teeb plhaub, lub hau me me thiab lwm yam. | |

| YG 25 | 13.4-14.8 Nws | ≥2480 | ≥82.5 | Tsim nyog rau kev ua pwm ntawm lub taub hau txias, txias stamping thiab txias nias siv rau kev tsim khoom txheem, bearings thiab lwm yam. | |

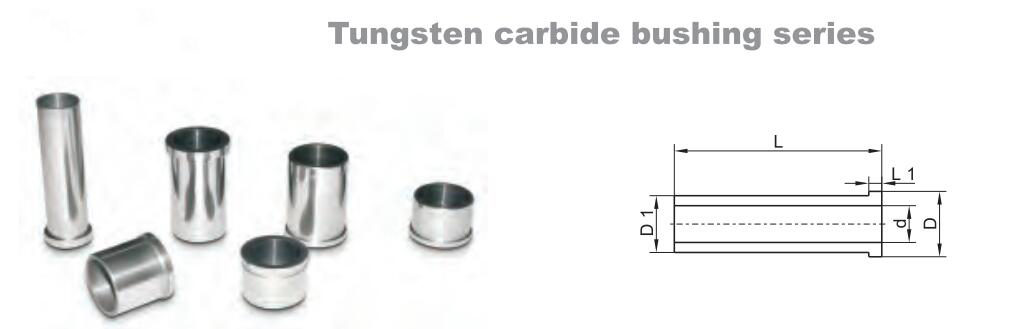

Dimension rooj

| Qauv No. | Specification | OD (D: hli) | ID (D1: hli) | Pore (d: hli) | Ntev (L: mm) | Kauj ruam Length (L1: mm) |

| KD-2001 | 01 | 16.41 Nws | 14.05 Nws | 12.70 Nws | 25.40 Nws | 1.00 Nws |

| KD-2002 | 02 | 16.41 Nws | 14.05 Nws | 12.70 Nws | 31.75 Nws | 1.00 Nws |

| KD-2003 | 03 | 22.04 Nws | 18.86 Nws | 15.75 Nws | 31.75 Nws | 3.18 |

| KD-2004 | 04 | 22.04 Nws | 18.86 Nws | 15.75 Nws | 50.80 Nws | 3.18 |

| KD-2005 | 05 | 16.00 Nws | 13.90 Nws | 10.31 Nws | 76.20 Nws | 3.18 |

| KD-2006 | 06 | 22.00 Nws | 18.88 Nws | 14.30 Nws | 25.40 Nws | 3.18 |

| KD-2007 | 07 | 24.00 Nws | 21.00 Nws | 16.00 Nws | 75.00 Nws | 3.00 Nws |

| KD-2008 | 08 | 22.90 Nws | 21.00 Nws | 15.00 Nws | 75.00 Nws | 3.00 Nws |

| KD-2009 | 09 | 19.50 Nws | 16.90 Nws | 12.70 Nws | 50.00 Nws | 4.00 Nws |

| KD-2010 | 10 | 36.80 Nws | 32.80 Nws | 26.00 Nws | 55.00 Nws | 4.00 Nws |