Cov khoom

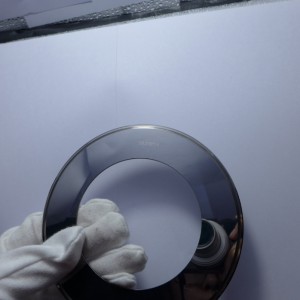

Blank Tungsten Carbide Wear Parts Mechanical Foob Rin

Khoom Description

Tungsten carbide foob rings yog dav siv nyob rau hauv cov roj refineries, petrochemical industries, chiv nroj tsuag, petrochemical nroj tsuag, tshuaj industries.Peb tshuab foob rings rau subsea roj thiab roj kev lag luam, qhov twg cov khoom lub neej tseem ceeb heev.Peb muab cov lus qhia txog cov khoom siv rau peb cov neeg siv khoom, kom ntseeg tau tias lawv cov nplhaib foob tau tsim los rau lawv qhov chaw ib puag ncig tshwj xeeb, txawm tias nws muaj kev cuam tshuam loj lossis tsis tu ncua.

Cov khoom lag luam thiab thev naus laus zis los ntawm Kedel tau siv dav hauv kev lag luam roj & roj, chemical engineering, subsea, nuclear fais fab thiab aerospace industries.Feem ntau siv hauv kev ua haujlwm hnyav xws li kev puas tsuaj loj, yaig, corrosion, kub kub, siab siab thiab muaj zog cuam tshuam.Peb cov neeg siv khoom loj yog cov tuam txhab nto moo thoob ntiaj teb.Kedel yog lub tuam txhab xa tawm ua lag luam nyob hauv Suav teb ntawm kev hnav-tiv taus cemented carbide cov khoom lag luam thiab cov txheej txheem siab precision machining.

Qhov zoo

1. 100% nkauj xwb raw khoom.

2. Kev soj ntsuam tuaj yeem muab tau.

3. Customized qhov chaw muaj.

4.High stability, ntev lifespan voj voog.

5. Nrog rau kev cob qhia xov xwm tshwj xeeb

Daim ntawv thov

Peb tab tom tsim Cemented tungsten Carbide Wear Parts rau kev lag luam sib txawv, tungsten carbide yog dav siv los ua lub ntsej muag nrog resistant hnav, siab tawg zog, siab thermal conductivity, me me tshav kub expansion co-npaum.Nws yog cov khoom siv zoo tshaj plaws los tiv thaiv tshav kub thiab tawg hauv txhua cov ntaub ntawv tawv tawv.

Peb tuaj yeem tsim ob qho tib si ntxhib dawb paug tungsten carbide foob rings thiab ua tiav cov nplhaib nrog siab precision.Nrog siab hnav tsis kam thiab zoo corrosion kuj, tungsten carbide khoom yog zoo dua li ceramic thiab silicon carbide khoom.

Ntau yam Valve

Pob

Txhua chav yuav raug ntim rau hauv lub tog raj kheej yas nrog ua npuas ncauj, tom qab ntawd muab tso rau hauv lub thawv ntawv.

Qib Cov Khoom thiab Cov Ntawv Pom Zoo ntawm Cemented Carbide

| Kedel Qib | Co | Qhov ntom | Hardness (HRA) | TRS |

| (Wt%) | (g / cm3) | (≥ N / mm²) | ||

| YG11-C | 9.0-11.0 Nws | 14.33-14.53 Nws | 88.6-90.2 ib | 2800 |

| YG15-C | 15.5-16.0 Nws | 13.84-14.04 dr hab | 85.6-87.2 ib | 2800 |

| YG 15 X | 14.7-15.3 Nws | 13.85-14.15 dr hab | ≥89 | 3000 |

| YG 20 | 18.7-19.1 Nws | 13.55-13.75 dr hab | ≥83.8 | 2800 |

| yog 06x | 5.5-6.5 | 14.80-15.05 dr hab | 91.5-93.5 Nws | 2800 |

| YG08 | 7.5-8.5 Nws | 14.65-14.85 dr hab | ≥89.5 | 2500 |

| YOG 09 | 8.5-9.5 Nws | 14.50-14.70 dr hab | ≥89 | 2800 |

| YG 10 X | 9.5-10.5 Nws | 14.30-14.60 dr hab | 90.5-92.5 Nws | 3000 |