Cov khoom

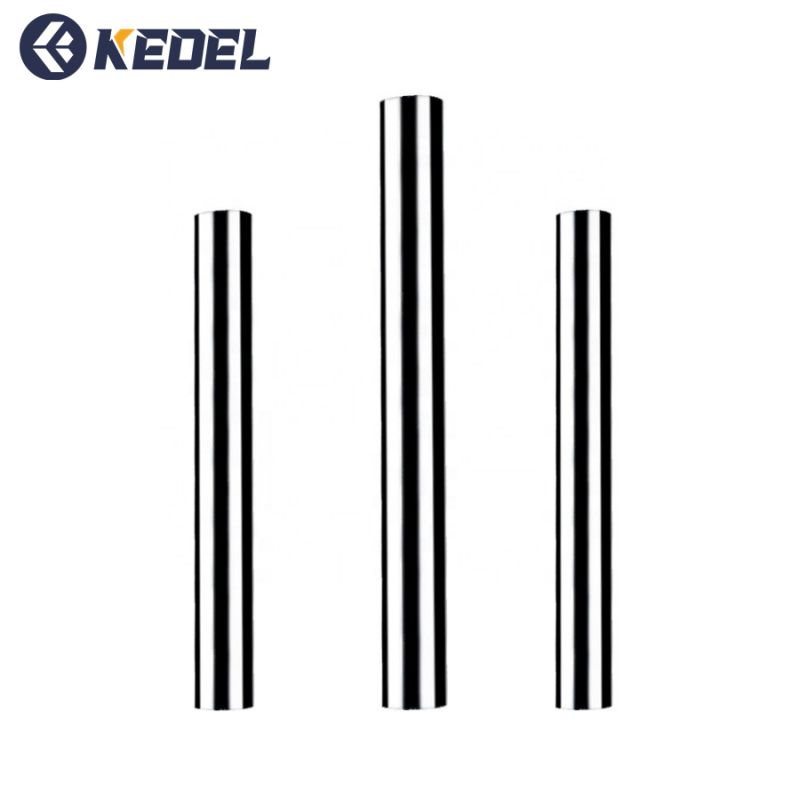

Tungsten Khoom Carbide Rods

Carbide Rods Description

tungsten carbide rods yog dav siv los tsim cov khoom zoo carbide, xws li kawg mills, xyaum, reamers, milling cutters, stamping, thiab ntsuas cov cuab yeej hauv kev lag luam sib txawv.Kedel Tool manufactures sab saum toj thiab zoo sib xws carbide rods nyob rau hauv ntau qib xws li K20F, K25F , thiab lwm yam. Peb muab ob qho tib si hauv av thiab hauv av carbide rods.Cov txheej txheem kev xaiv ntawm tungsten carbide rods nyob rau hauv ntau qhov ntev yog muaj, thiab peb kuj muab kev pabcuam customization raws li koj xav tau.Raws li ISO cov chaw tsim khoom, Kedeltool siv cov ntaub ntawv zoo tshaj plaws los lav qhov zoo thiab kev ua haujlwm ntawm peb cov carbide rods.Nrog kev soj ntsuam nruj nruj, peb tuaj yeem ua kom zoo ib yam hauv txhua pawg.

Kedel Carbide Qws Hom

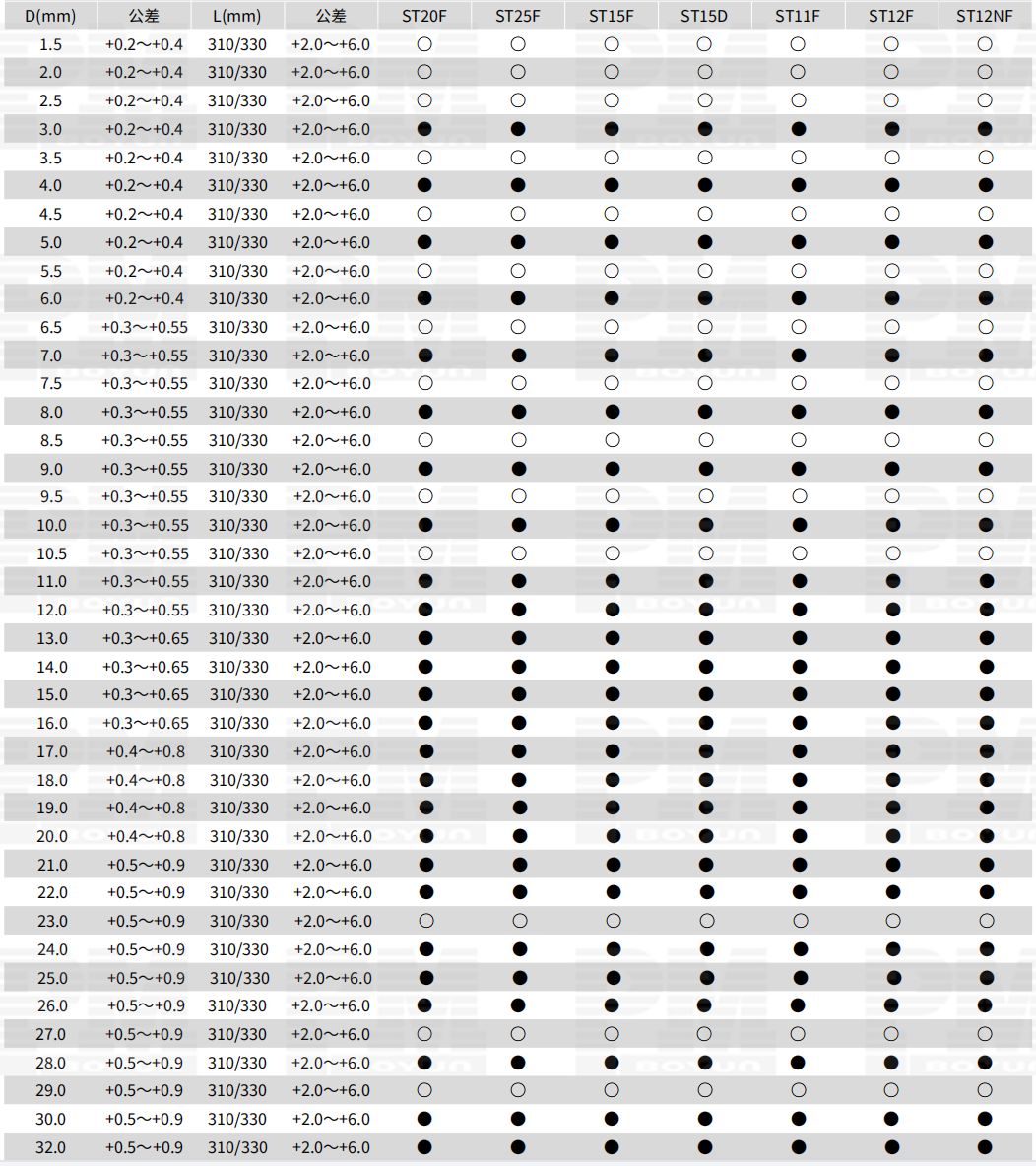

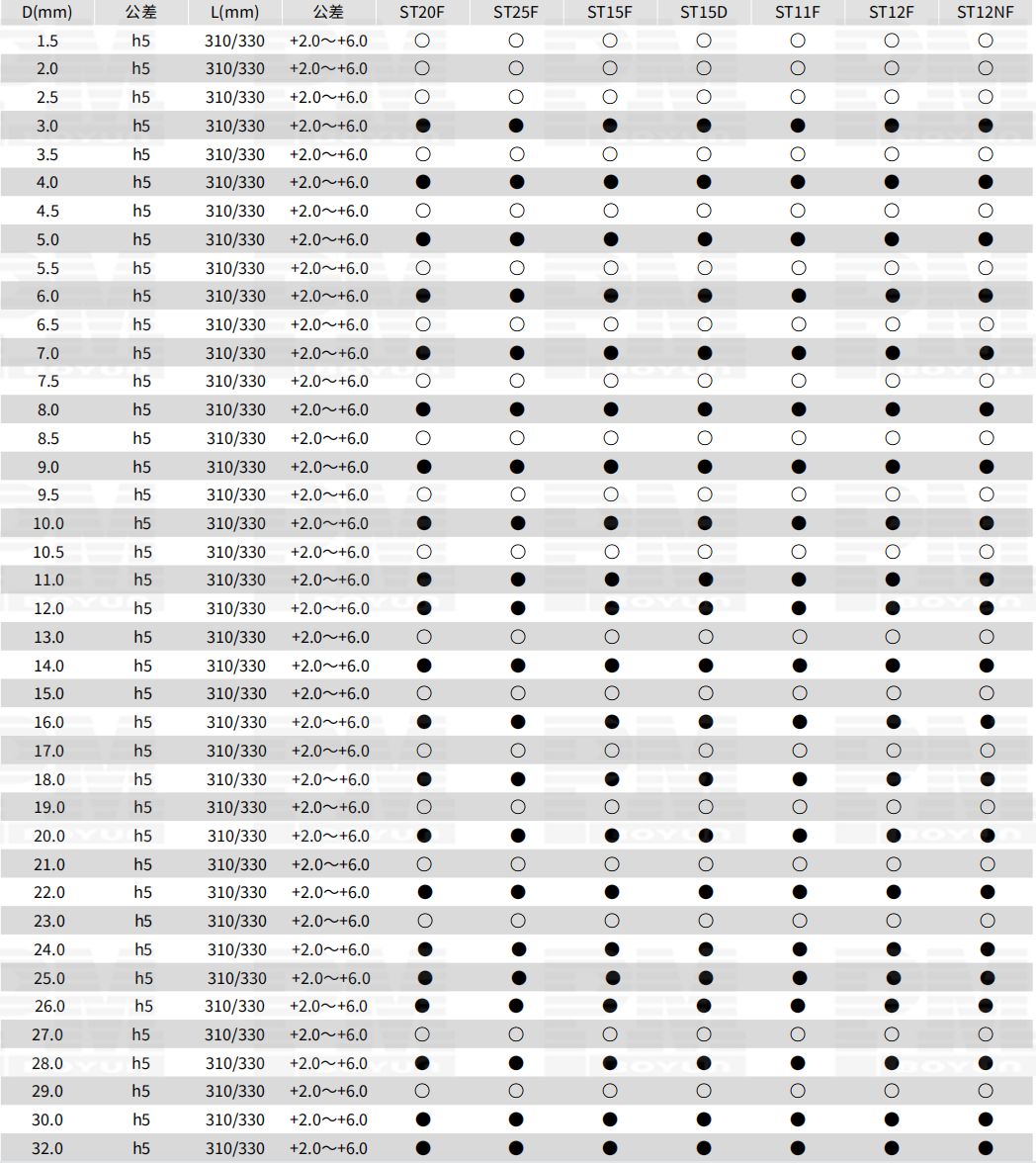

1. Khoom Carbide Rods hauv Metrics

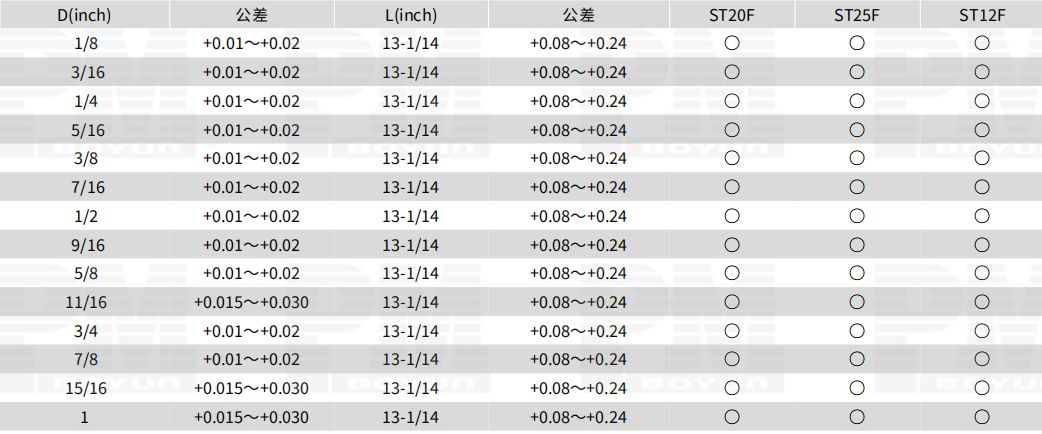

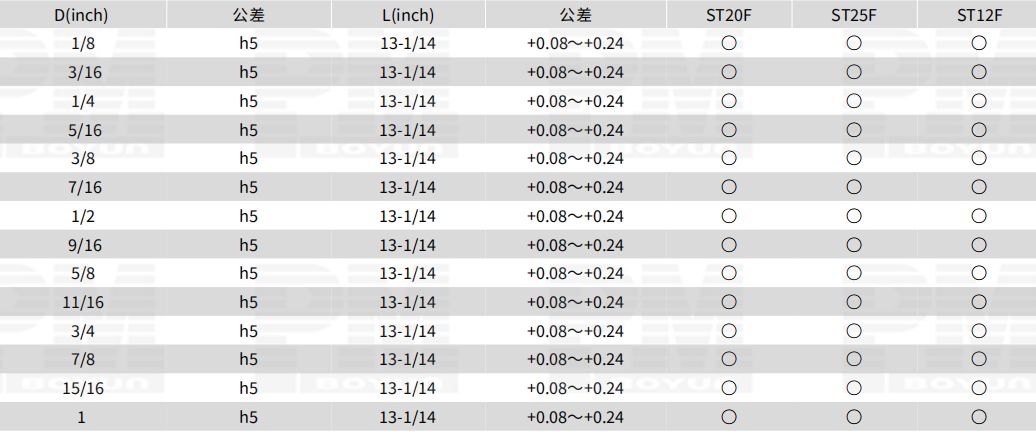

2. Khoom Carbide Rods hauv nti

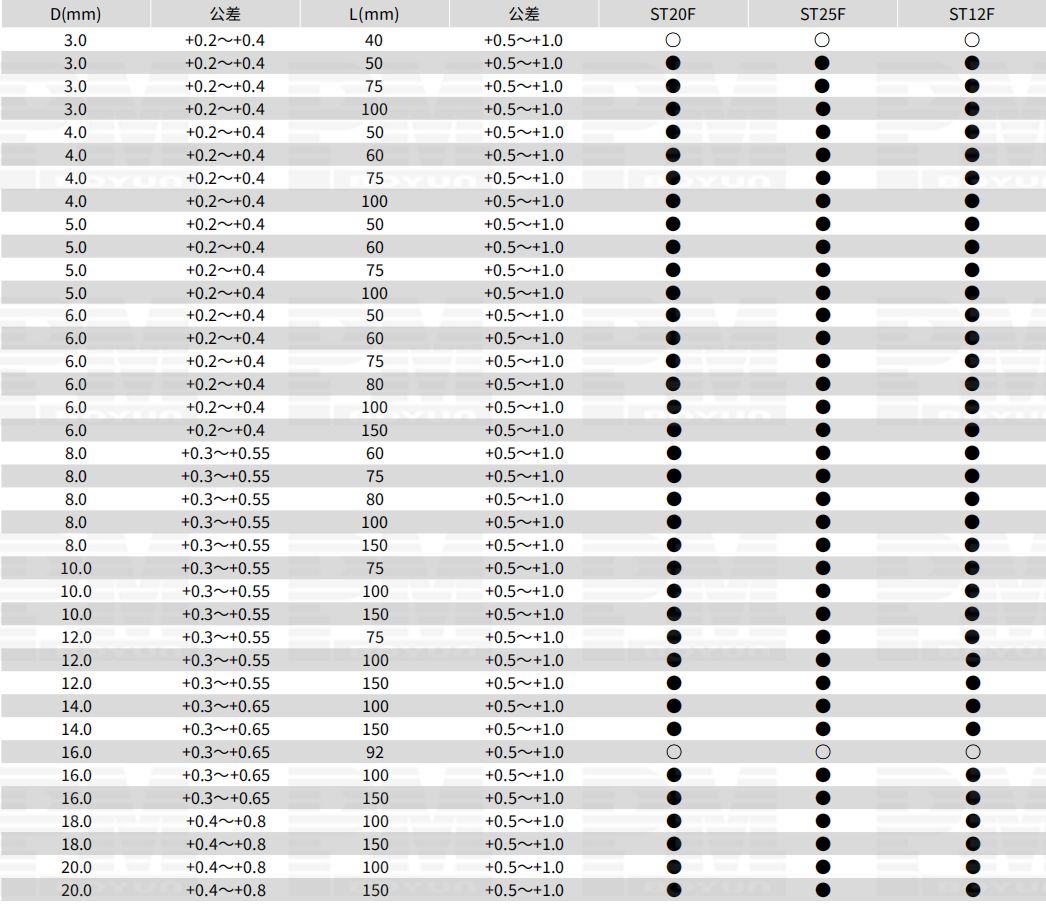

3. Drill Blanks (Chamfered)

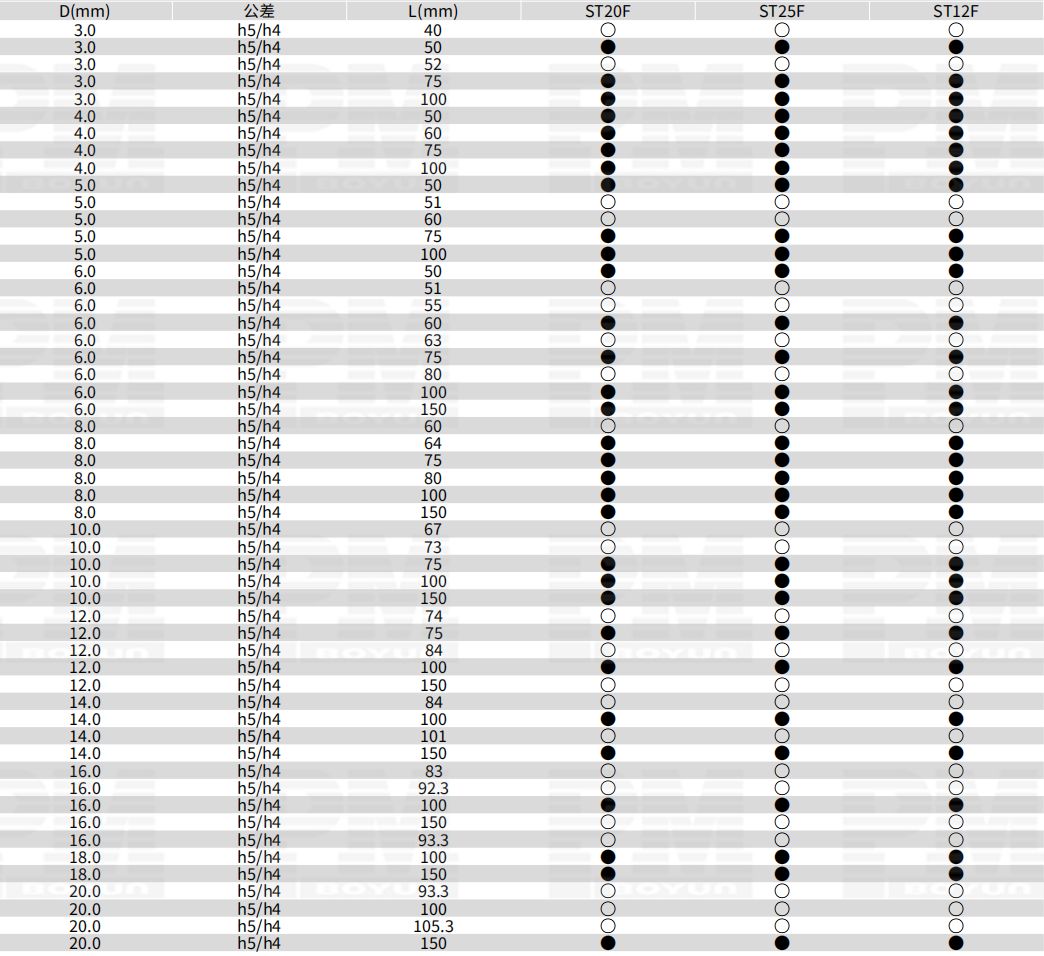

4. End Mill Blanks (Chamfered)

5. Carbide Rods nrog Lub Qhov Ncauj Ncaj Ncees

6. Carbide Rods nrog ob lub qhov dej txias txias

Carbide qws yam ntxwv

1. Ua los ntawm cov khoom zoo tungsten carbide superfine hmoov

2. Cov khoom siv Precision nrog 10MPa HIP-Sinter qhov cub txheem tsim khoom.

3. High hardness thiab siab zog

4. Tshwj xeeb zoo: liab hardness, hnav resistant, siab elasticity modulus, TRS, tshuaj stability, feem resistant, tsis tshua muaj dilatation coefficient, tshav kub conduction thiab hluav taws xob conduction tib yam hlau.

5. Kev siv tshuab tshwj xeeb: kev kub siab sintering ntawm lub tshuab nqus tsev kub.Txo porosity, txo compactness thiab txhua yam khoom.Ntau qib, hom thiab ntau thiab tsawg.

6. Qib sib txawv rau koj siv.

Qhov Loj

Cov npe qeb

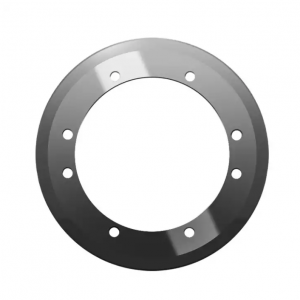

| Qib Taw Qhia rau Carbide Rods | |||||||

| Qib | Cov% | WC grain loj | HRA | HV | Qhov ceev (g / cm³) | Bending zog (MPa) | Fracture toughness (MNm-3/2) |

| KT 10 F | 6 | Submicron | 92.9 ua | 1840 | 14.8 ib | 3800 ib | 10 |

| KT10 UA | 6 | superfine | 93.8 ua | 2040 | 14.7 ib | 3200 | 9 |

| KT 10 NF | 6 | nanometer | 94.5 ua | 2 180 | 14.6 ib | 4000 | 9 |

| KT 10 C | 7 | Zoo | 90.7 ua | 1480 | 14.7 ib | 3800 ib | 12 |

| KT 11 F | 8 | Submicron | 92.3 ib | 1720 | 14.6 ib | 4 100 | 10 |

| KT11 UA | 8 | superfine | 93.5 ua | Xyoo 1960 | 14.5 Nws | 3000 | 9 |

| KT 12 F | 9 | superfine | 93.5 ua | Xyoo 1960 | 14.4 ib | 4500 | 10 |

| KT 12 NF | 9 | nanometer | 94.2 ib | 2100 | 14.3 | 4800 ib | 9 |

| KT15D | 9 | Submicron | 91.2 ib | 1520 | 14.4 ib | 4000 | 13 |

| KT 15 F | 10 | Submicron | 92.0 ua | 1670 ib | 14.3 | 4000 | 11 |

| KT 20 F | 10 | Submicron | 91.7 ua | 1620 | 14.4 ib | 4300 ib | 11 |

| KT 20D | 10 | Submicron | 92.0 ua | 1670 ib | 14.3 | 4500 | 11 |

| KT 25 F | 12 | superfine | 92.4 ua | 1740 ib | 14.1 | 5 100 | 10 |

| KT 25 EF | 12 | superfine | 92.2 ib | 1700 | 14.1 | 4800 ib | 10 |

| KT 25D | 12 | superfine | 91.5 ua | 1570 ib | 14.2 | 4 200 | 13 |

| KT37 NF | 15 | nanometer | 92.0 ua | 1670 ib | 13.8 ib | 4800 ib | 10 |

Yog xav paub ntxiv (MOQ, nqe, xa khoom) lossis yog tias koj xav tau cov kev pabcuam customization, thov thov qhov kev tsocai.